What are slip-on flanges and how are they used?

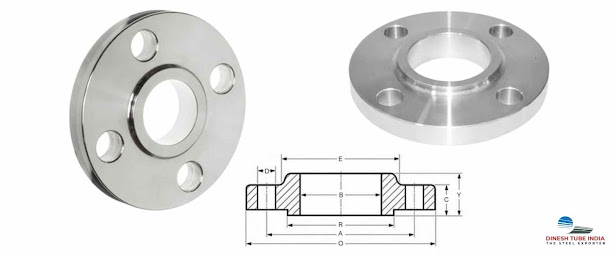

Typical slip on flanges is designed to accept pipe into the bore/centre of the flange slip on to allow welding both on the outside diameter (OD) of the pipe and on the interior side of the connection. You may recognize them: Because the slip-on flange welding do not have a weld bevel, they provide an excellent alternative to weld necks, allowing the pipe to be adjusted in length according to its position. As the bore of the slip on weld flange is large enough for the matching pipe, there should be enough room for it to fit. Welders and fabricators can make the connection with enough space. Applications involving lower pressures are extremely common with this flange type. Main characteristics of the slip-on flange Slip flanges are popular because of their low material cost and ease of installation. The flanges can also be used as lap-joint flanges if Type B or Type C ends are being handled. There are models with low pressures and a variety of diameters to choose from. Due