What are slip-on flanges and how are they used?

Typical

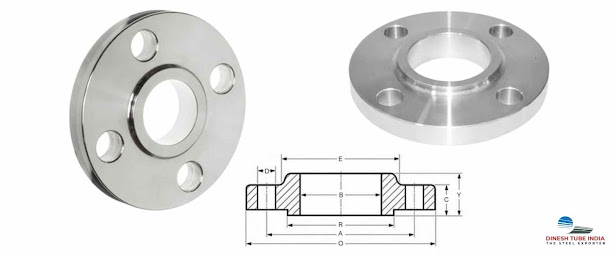

slip on flanges is designed to accept pipe into the bore/centre of the flange

slip on to allow welding both on the outside diameter (OD) of the pipe and on

the interior side of the connection. You may recognize them:

Because

the slip-on flange welding do not have a weld bevel, they provide an excellent

alternative to weld necks, allowing the pipe to be adjusted in length according

to its position.

As

the bore of the slip on weld flange is large enough for the matching pipe,

there should be enough room for it to fit. Welders and fabricators can make the

connection with enough space.

Applications

involving lower pressures are extremely common with this flange type.

Main

characteristics of the slip-on flange

Slip flanges are popular because of their

low material cost and ease of installation. The flanges can also be used as

lap-joint flanges if Type B or Type C ends are being handled.

There are models with low pressures and a

variety of diameters to choose from. Due to the absence of a neck to rest on the

pipe, this flange must be double welded instead of welding neck flanges.

In dimensional terms, most slip-on flange hubs

will resemble raised faces.

There are instances when a “ring style”

slip-on without a hub would be appropriate if space is limited. It is still

permissible to call ring-style slip-ons without hubs slip-ons, despite the

popularity of hub-style slip-ons.

Slip-ons with higher pressures often have a

lap joint-like height to provide better connection. It is sometimes preferred

by customers to use a pipe slip with a machined hub that resembles a lap joint

when a lap joint is not readily available or hub height is not a concern.

It is more common to find slip on pipe flanges

in lower-pressure assemblies when a higher-stress service requires a superior

connection. In contrast, weld neck flanges are reinforced on the hub and form

weld bevel connections directly to the buttweld end of pipes instead of using

slip-on style flanges. Tapered hubs are more effective at handling mechanical

stress.

How do

slip-on flanges work?

Before welding, slip-on flanges must be

inserted into the pipe. As can be seen in this case, there are two welds, which

provide durability and prevent leaks. There is approximately a two-thirds

reduction in the pressure resistance of welding neck flanges when using these

flanges. Suitable for low-pressure applications, slip-on flanges are convenient

to install and weld onto a variety of pipes. A cost-effective manufacturing

process is also another advantage of welding.

For slip-on flanges to be mounted, there does

not need to be much longitudinal space. It is also easier to align the pipes

without having to cut them exactly.

Read More About This Article

On Our Website For More information: https://thesteelexporter.com/what-are-slip-on-flanges-and-how-are-they-used/

#design #architecture #interiordesign #steel #art #garden #gardendesign #rust #gardening #sculpture #metal #welding

Comments

Post a Comment